Pebbledashing - Application Tips

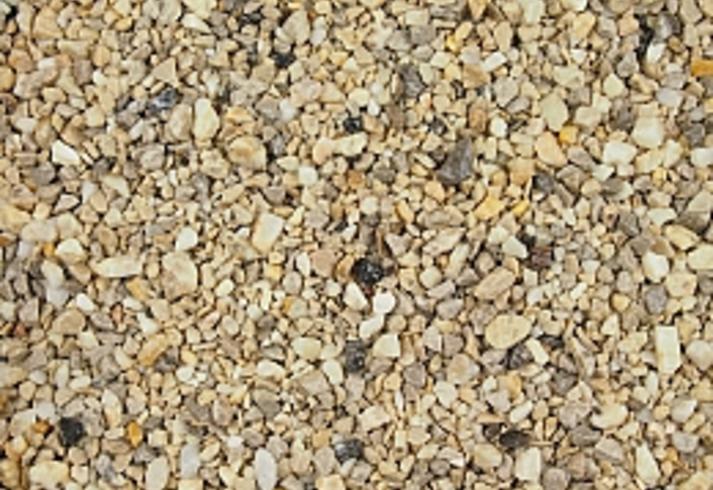

The aggregates used for dry-dashing are predominantly naturally occurring minerals that will have colour variations that allows little control over colour consistency.

At Derbyshire Specialist Aggregates, a lot of care is  taken to reduce any colour inconsistencies, however this can never be 100% guaranteed. It is important to ensure that the aggregates used are from the same manufactured batch in order to reduce any potential colour matching issues.

taken to reduce any colour inconsistencies, however this can never be 100% guaranteed. It is important to ensure that the aggregates used are from the same manufactured batch in order to reduce any potential colour matching issues.

No aggregate should be applied directly from the bag that it was supplied in, as any fines contained in the bag will usually fall towards the bottom of the bag and this can cause patching when applied, this is where an area with a higher percentage of fines will differ in texture, colour and finish to an area dashed with aggregates containing little or no fines. All dashing aggregates should be decanted from the bags into a clean drainable container (i.e. a plasterer's bath) and blended with 3 to 4 other bags ensuring that the colour and any fines are mixed evenly within the container prior to application.

Dashing aggregates supplied by Derbyshire  Specialist Aggregates do not require any further washing at this stage and care should be taken to ensure that the moisture content within the aggregates will not effect the performance of the render to which it is being applied. This blending process should be repeated throughout the application with more aggregate being added as the material is being applied. With dry-dash finish and certain textured finishes, it is essential for the final coat to remain soft for a longer time than normal. This can be assisted through reducing the suction of the undercoat by a more thorough wetting down, or including a water-retaining admixture in the final render coat.

Specialist Aggregates do not require any further washing at this stage and care should be taken to ensure that the moisture content within the aggregates will not effect the performance of the render to which it is being applied. This blending process should be repeated throughout the application with more aggregate being added as the material is being applied. With dry-dash finish and certain textured finishes, it is essential for the final coat to remain soft for a longer time than normal. This can be assisted through reducing the suction of the undercoat by a more thorough wetting down, or including a water-retaining admixture in the final render coat.

The aggregate should be applied in a damp but not soaked state as this helps with the adhesion to the render. Care should be taken to ensure that the moisture content of both the aggregate and the render is consistent as differentials caused by atmospheric conditions can create problems, such as dashing the same elevation in changeable weather on the same day.

not soaked state as this helps with the adhesion to the render. Care should be taken to ensure that the moisture content of both the aggregate and the render is consistent as differentials caused by atmospheric conditions can create problems, such as dashing the same elevation in changeable weather on the same day.

Derbyshire Specialist Aggregates does not recommend the re-use of aggregate that has been collected up following the first application. Any aggregate that has been walked on or exposed to any substance that could contaminate it should be disposed of in the responsible way and not re-used as a dashing aggregate.

For more information, advise or samples, please do not hesitate to Contact Us or email sales@derbyaggs.com or call on 01629 636500